Astigmatism in Advanced Microscopy - When Standard Dichroics Aren't Enough

Astigmatism artifacts in advanced microscopy techniques frequently trace back to an unexpected culprit: the dichroic mirror. This issue manifests distinctly in different applications, making diagnosis straightforward once you know what to look for.

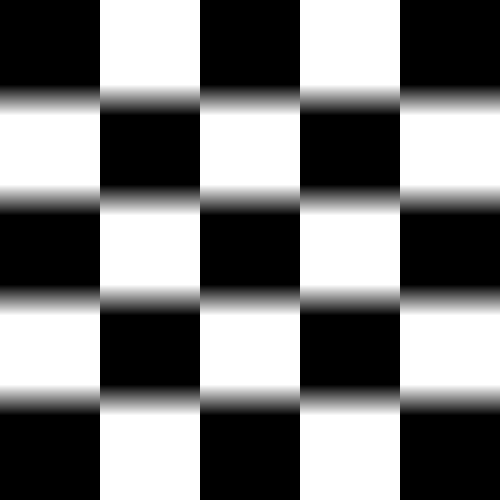

Recognizing the Problem

In SIM, the checkerboard pattern used to calibrate the spatial light modulator provides a clear diagnostic. Astigmatism causes pattern edges to focus at different depths depending on their orientation. When edges along one direction appear sharp, those at 90 degrees remain blurred.

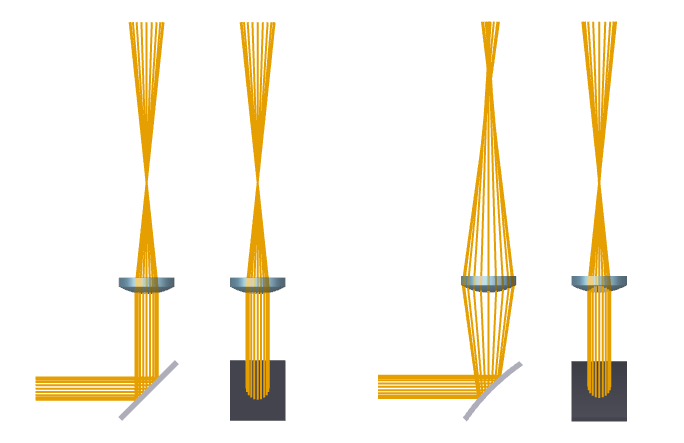

TIRF presents a different signature. During beam collimation at infinity (focusing in the back focal plane), astigmatism prevents achieving a sharp circular focus. Instead, moving through the focus produces orthogonal lines, each appearing at different depths.

The Underlying Cause

Dichroic mirror deformation creates the astigmatism, specifically because this deformation occurs unevenly. When mounted, mirrors not designed for demanding applications exhibit greater deformation along their long edge compared to the short edge. This differential deformation creates different curvatures in perpendicular directions - the textbook definition of astigmatism.

The asymmetric stress pattern means light rays traveling in one orientation encounter different optical path lengths than those at 90 degrees, resulting in separate focal planes for perpendicular features.

Resolution

Manufacturers like Semrock distinguish between widefield and super-resolution/TIRF applications on their flatness specifications (I am not affiliated with IDEX-HS/Semrock). However, applications like SIM - which would benefit from super-resolution/TIRF-grade dichroics - aren't always explicitly mentioned.

Standard dichroics for widefield microscopy use 1mm thickness. Thicker options of 2mm and 3mm offer superior flatness and reduced mounting deformation for demanding applications, though at higher cost.